Robust, hard wearing, reliable and highly accommodating

Rubber diaphragm mechanical seals provide enhanced seal capability, performance and life. That is why they are one of the most widely used mechancial seal types.

How do rubber diaphragm seals work?

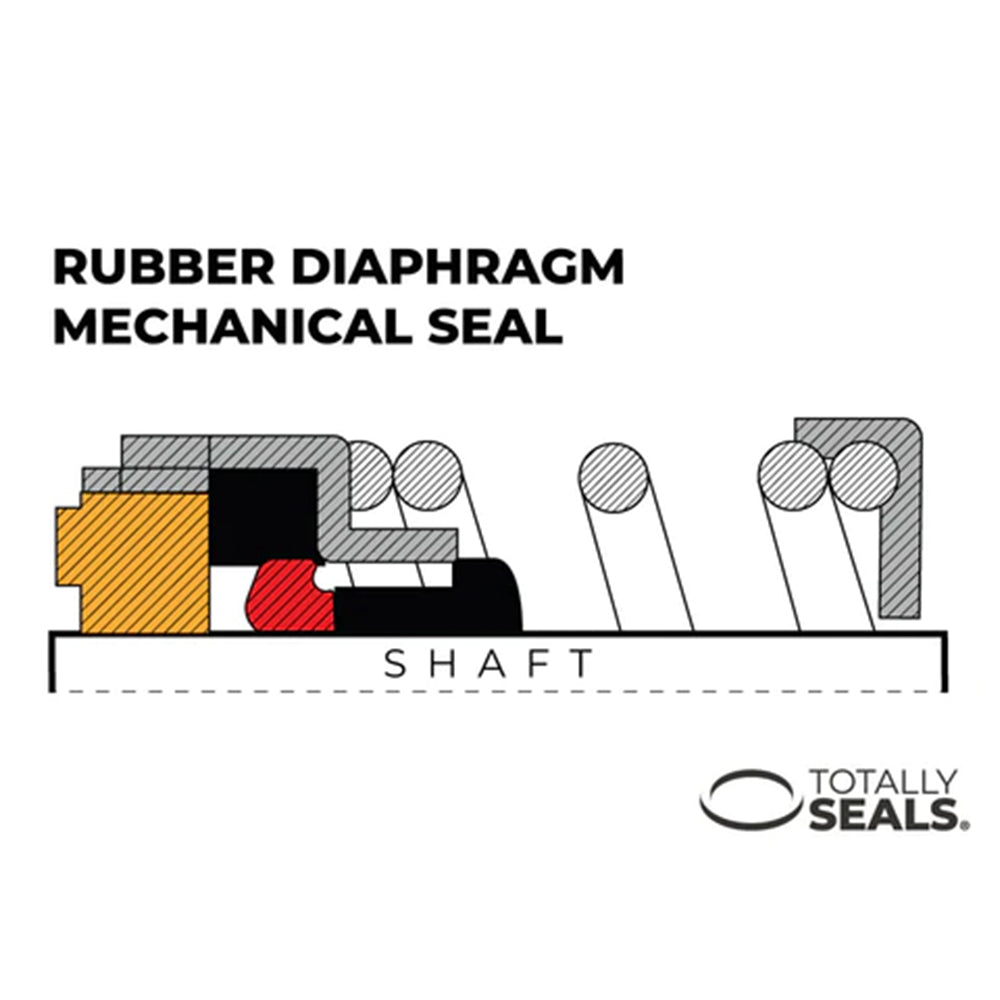

The diagram above shows the standard section of a rubber diaphragm seal. The shaft seal is provided by the rubber diaphragm which is squeezed onto the shaft by the drive ring. Once fitted, the rubber diaphragm will grip the shaft giving a strong static seal and very positive drive, via the drive ring, to the seal face.

As there is no relative movement between the shaft and the rubber diaphragm, shaft fretting, wear and hang-up hysteresis are eliminated and the seal can immediately accommodate some shaft run-out and misalignment.

Shaft axial movement and the movement required during the working life of the seal is handled by the elastomer rubber flexing at its junction point (Red Area on diagram). The seal head automatically adjusts to compensate for any face misalignment, usually caused by shaft end float / pump body misalignment.

The closing spring force and the seal pumping pressure force maintain the faces in full contact, whilst the rubber diaphragm acts as an elastomeric bellows providing sustained flexibility. The positive drive of the seal face is transmitted via the drive ring and retaining housing, and not via the spring, which merely provides some closing force to the mechanical seal faces. These seals can therefore be used to seal shafts rotating in either direction and in vacuum applications.

Examples of rubber diaphragm mechanical seals

Once fitted, the rubber diaphragm will grip the shaft giving a strong static seal and very positive drive, via the drive ring, to the seal face.

Need help with a rubber diaphragm mechanical seal?

Our expert team are on hand to help you.

Order before 2pm to get same day dispatch next day delivery

Our Mechanical Seals range

Check out our extenisve mechanical seal range, including replacement seals for most major manufacturers: Eagle Burgmann, John Crane, Roten/Uniten, AES, Alfa Laval, Grundfos, MTU, PAC-Seal, US Seal and more.

Looking for the perfect seal?

-

Identify the seal you need

Use toolIndentify the seal you need using our Mechanical Seal Idenitifcation tool by selecting the key design features.

-

Know your material

View guideFind out the ideal seal material for your requirement using our Mechanical Seals Materials Guide.

-

Check Chemical Compatibility

Check materialsUse our compatibility checker to ensure you are using the most effective material for your seal.